25 years of professional expertise. Rigorously tested. Powered by proprietary ZENESIS™ pattern Diamond technology.

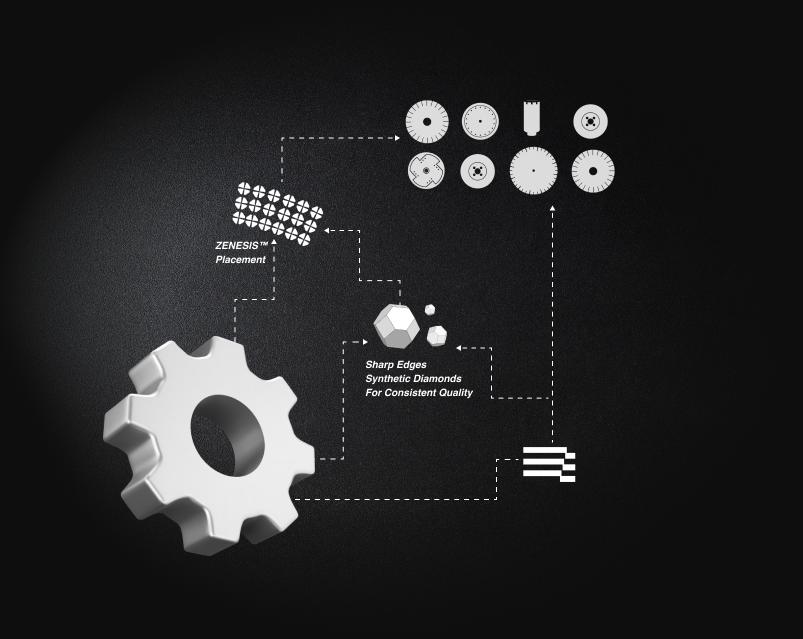

ZENESIS™ Tile & Stone features the ZENESIS™ Placement Technology, delivering diamond tools further with up to 70% longer life and up to 70% faster cuts.

THE GENESIS OF ZENESIS™

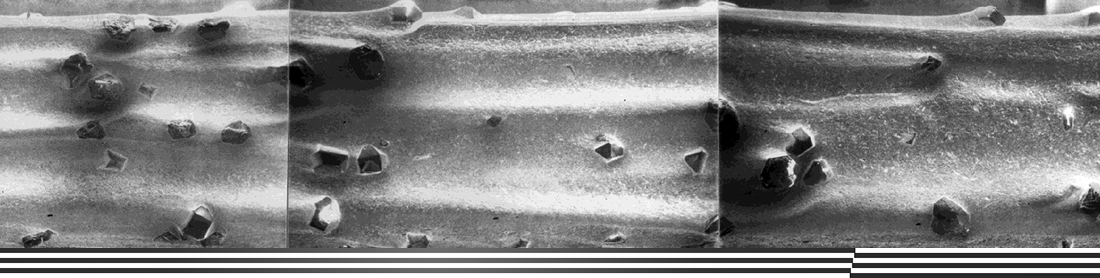

Original conventional diamond segments, also called random diamond segments, are created by blending various metal powders with particular sizes and amounts of industrial diamonds. They are thoroughly mixed before being put into a mold that is then pressed and heated until they create a solid segment.

CONVENTIONAL NON-PATTERNED DIAMOND TOOLS

ZENESIS™ PATTERNED

TECHNOLOGY:

FROM THE COMPANY THAT STARTED

A REVOLUTION

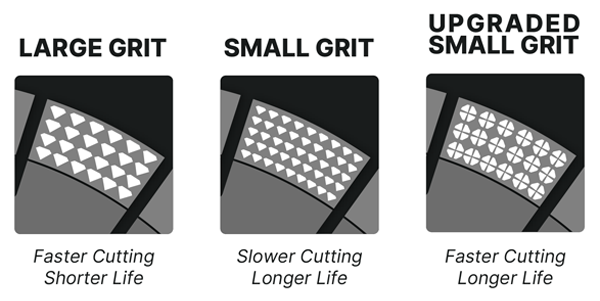

Patterning technology has been around since the 1960s; however, the performance achieved through the even distribution of the diamond grit did not justify the added complexity in manufacturing. Through years of intensive research and development, our engineers at ZENESIS™ have refined our proprietary patterned diamond technology to achieve maximum cutting performance without sacrificing the life of the tool or quality of cut. Our pattern exposes the ideal number of the highest-quality diamonds throughout the life of the tool, providing consistent performance from start to finish.

0

%

Cutting Speed

Up to 70% faster*

70

%

Tool Life

Up to 70% longer*

A QUANTUM LEAP FORWARD IN ZENESIS™ DIAMOND TECHNOLOGY

By combining layering techniques with an extraordinary degree of precision, we ensure that our high-quality diamonds will always be evenly exposed throughout the segment to allow faster cutting and efficient debris removal. We’ve rigorously exacted our manufacturing processes to ensure a perfect pattern – cut after cut.

For our most innovative blade offering, ZENESIS™ takes this process one step further by optimizing the distribution and concentration of diamonds on the segments to deliver raw cutting power where it is needed most. Optimal performance is achieved as the strategic placement of diamonds virtually removes all cutting inefficiencies.

We care about your safety while you operate diamond tools.

Warning & Caution Information

1. Do not operate saw machine unless proper saw

guard is

in place

2. Always wear eye protection, safety mask, ear protection and comply with ANSI Z87.1

and

all other safety guidelines as per ANSI B7.5 and all OSHA regulations i.e. 29 CFR

1910.94,

1910.95, 1910.133, 1910.215 & 1910.1000 covering handling, storage & inspection

–mounting –

safety guard – flanges – machine condition – ventilation & air contaminants, eye, ear &

other personal protection information.

3. Always mount blade securely in proper rotation direction. Make sure that arbor and

flanges are clean, and tighten nut securely.

4. Mount the blade on the correct diameter arbor shaft.

5. Do not use blade on saw machine that will exceed maximum recommended blade RPM.

6. Inspect the blade before each use for excessive wear, core crack, core flatness and

arbor

damage. Discard damaged or cracked blade.

7. Before performing any cutting operations, let the tool run for a few seconds without

load. If blade wobbles, vibrates or unusual noise occurs, stop the tool immediately.

Examine

the blade for damage or incorrect mounting.

8. The diamond blade is intended for straight line cutting only. Cutting curves will

cause

stress cracks or fragmentation on the blade, resulting in possible injury to people in

the

vicinity.

9. Consult your saw operations manual for important safety instructions and

warnings.

10. Failure to heed all safety instructions and warnings could result in serious injury.

Zenesis is a trademark of EHWA Diamond Inc.

1. No opere la sierra eléctrica a menos que el

dispositivo de seguridad de la

cuchilla se encuentre en su lugar.

2. Utilice siempre protección para los ojos, máscara de seguridad, protección auditiva y

cumpla con las norma ANSI Z87.1 y las demás directrices de seguridad en conformidad con

ANSI

B7.1, B7.5 y las reglamentaciones de la OSHA 29 CFR 1910.94, 1910.95, 1910.133,

1910.134,

1910.215, y 1910.1000 concernientes a la información sobre seguridad personal,

manipulación,

almacenamiento y revisión, montaje, dispositivo de seguridad, bridas, acondicionamiento

del

aparato, ventilación y contaminantes del aire, protección visual y auditiva.

3. Siempre instale la cuchilla de manera segura y en la dirección de rotación correcta.

Asegúrese de que el eje giratorio y las bridas estén limpios y las tuercas estén

apretadas

firmemente.

4. Instale la cuchilla en el diámetro correcto del eje.

5. No utilice una cuchilla que exceda las RPM máximas recomendadas para la cuchilla.

6. Revise la cuchilla antes de utilizarla para ver si hay daños en el eje, desgaste

excesivo, fisuras o uniformidad en el eje. Deseche cualquier cuchilla dañada o

agrietada.

7. Antes de realizar cualquier operación de corte, permita que la sierra opere

libremente

durante unos cuantos segundos. Si la cuchilla tambalea, vibra o produce algún ruido

anormal,

apague la herramienta de inmediato. Revise la cuchilla para ver si tiene algún daño o

está

instalada de manera incorrecta.

8. La cuchilla de diamante está diseñada para cortes rectos únicamente. Los cortes

curvilíneos pueden causar grietas por tensión o ruptura de la cuchilla, lo cual puede

resultar en lesiones en personas cercanas.

9. Consulte el manual de instrucciones de la sierra para informarse sobre las pautas de

seguridad y algunas advertencias.

10. Existe el riesgo de graves lesiones sino se tiene en cuenta las instrucciones de

seguridad.

Zenesis es una marca registrada de EHWA Diamond Inc.

1. Ne faites pas fonctionner cette scie si le dispositif de protection de la lame

approprié n'est pas en place.

2. Portez toujours des lunettes et un masque de sécurité, ainsi qu'un protecteur

d'oreilles, et respectez la norme ANSI Z87.1 et toutes les autres directives relatives à

la sécurité

conformément à la norme ANSI B7.5 et à tous les règlements de l'OSHA, à savoir 29 CFR

1910.94, 1910.95, 1910.133, 1910.215 & 1910.1000 couvrant les manipulations,

l'entreposage et les inspection - le montage - les dispositifs de protection - les

brides - l'état des

machines - la ventilation et les contaminants dans l'air, et des informations sur la

protection des yeux et des oreilles ainsi que d'autres équipements de protection

personnelle.

3. Montez toujours solidement la lame dans le sens de rotation correct. Assurez-vous que

l'arbre et les brides sont propres, et serrez l'écrou à fond.

4. Montez la lame sur l'arbre du diamètre approprié.

5. N'utilisez pas une lame sur la scie dépassant la vitesse de rotation de lame maximum

recommandée.

6. Inspectez la lame avant chaque emploi pour vous assurer qu'elle n'est pas

excessivement

usée, que le mandrin n'est pas fissuré ou aplati, et que l'arbre n'est pas endommagé.

Jetez

toute lame endommagée ou fissurée.

7. Avant de réaliser une quelconque opération de coupe, laissez l'outil fonctionner sans

contact avec l'ouvrage pendant quelques secondes. Arrêtez immédiatement l'outil si la

lame

tremble ou vibre, ou si vous entendez des bruits inhabituels. Examinez la lame pour

déterminer si elle est endommagée ou si elle a été montée de façon incorrecte.

8. La lame diamantée ne doit être utilisée que pour couper en ligne droite. Les coupes

curves entraîneront des fissurations ou des fragmentations de la lame résultant du

stress,

ce qui risque de causer des blessures aux personnes se trouvant à proximité.

9. Consultez votre manuel d'utilisation de la scie pour y lire des consignes de sécurité

et

des avertissements importants.

10. Le non-respect de ces consignes de sécurité et de ces avertissements pourrait causer

des

blessures graves.

Zenesis est une marque déposée de EHWA Diamond Inc.